PAX3D – Where Materials, Design, and Performance Converge

Our PAX3D Process

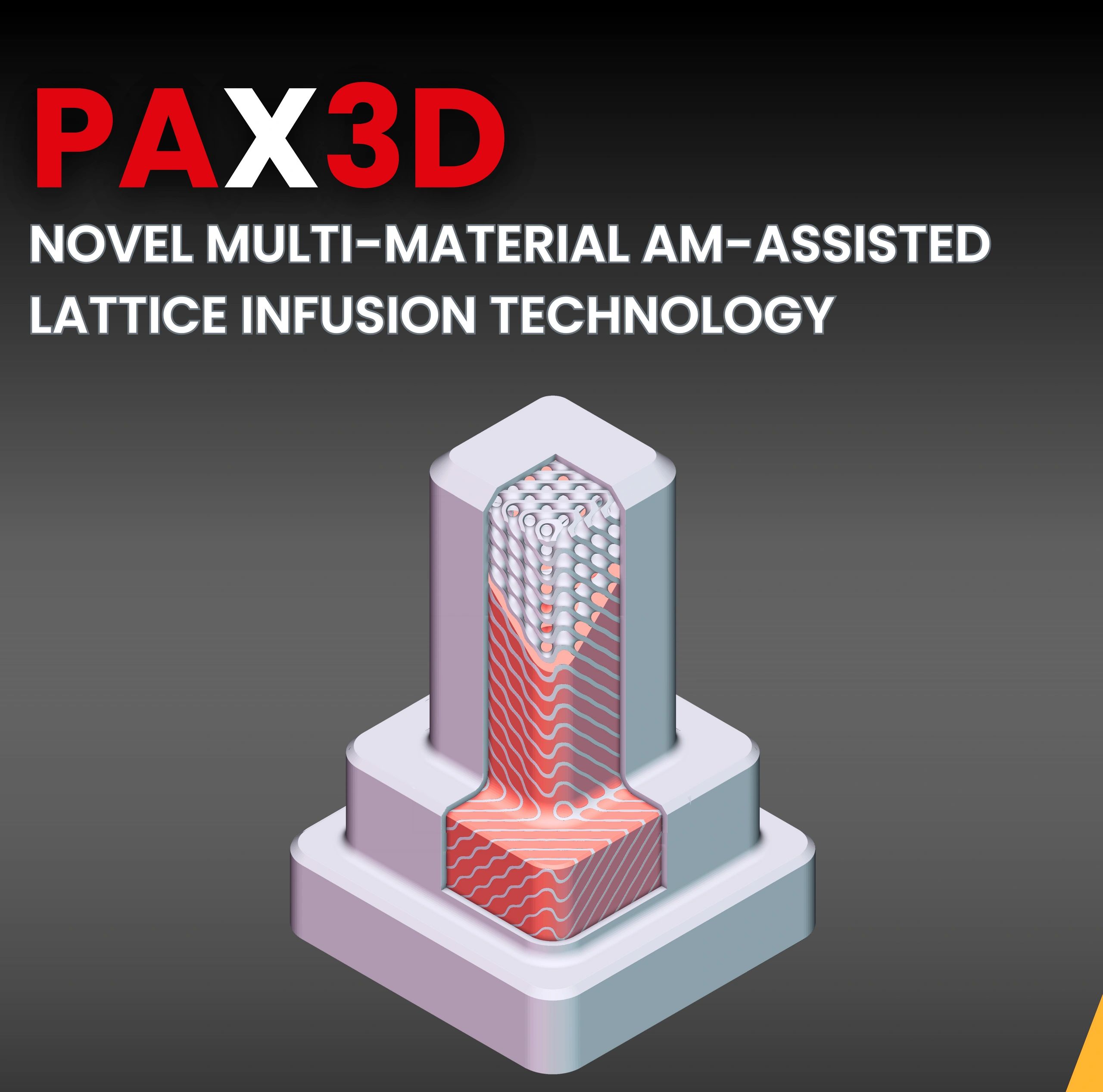

PAX3D is Formions Technologies’ proprietary hybrid manufacturing process, engineered to deliver high-performance, multi-material components with site-specific control over thermal and mechanical properties.

PAX3D: Hybrid Multi-Material Manufacturing for the Next Gen

Why Conventional Approaches Fall Short

Industries such as aerospace, electronics, tooling, and energy demand materials that can withstand high mechanical loads while efficiently dissipating heat.

- High-conductivity metals like copper and aluminum lack the strength to survive demanding environments.

- High-strength steels and titanium alloys suffer from poor thermal conductivity, causing overheating and failure.

- Exceptional options like tungsten or molybdenum are costly, heavy, and difficult to process.

- Even with Additive Manufacturing (AM) cooling channels, the bulk material remains a thermal bottleneck.

Result: performance losses, downtime, and costly thermal management add-ons.

The PAX3D Advantage

PAX3D is Formions’ proprietary Pressure Assisted 3D metal infusion technology — a breakthrough hybrid process combining AM with a patented infusion step, seamlessly integrated with heat treatment.

- Hybrid Architecture: High-strength outer shell (up to 1400 MPa) fused with a thermally conductive reinforced core (>700 MPa).

- Thermal Performance: Conductivity of 150–200 W/m·K, several times higher than steels, ensuring rapid heat dissipation and longer part life.

- One-Part, Multi-Function: Structural strength + thermal regulation integrated into a single engineered component.

Superior to Other Techniques

Unlike conventional AM or fully solid metal approaches, PAX3D:

- Cuts cost by reducing AM print volume, saving material and machine time.

- Eliminates extra processing — hybridization is embedded within post-processing.

- Optimizes performance-to-cost ratio, enabling industrial adoption at scale.

- Unlocks design freedom with site-specific property tuning using graded lattice structures.

Unlocking New Industrial Possibilities

With PAX3D, components are no longer bound by single-property trade-offs.

- Aerospace & Defense: Lightweight, thermally optimized, high-strength parts for extreme environments.

- Energy & EV Systems: Heat-critical components with enhanced reliability and longer service life.

- Tooling: Inserts and dies with conformal cooling and high wear resistance.

- Medical Devices: Tailored mechanical and thermal performance within complex geometries.

PAX3D redefines what is possible — stronger, cooler, smarter parts built for the future of manufacturing.

Read more technical details here !!

A PAX3D-manufactured Multi-Material Die Insert.

Why PAX3D?

Smart Engineering, Lower Costs

Suitable Mechanical Performance

Smart Engineering, Lower Costs

PAX3D Hybrid inserts reduce AM manufacturing costs by 27% compared to traditional solid steel.

Superior Thermal Performance

Suitable Mechanical Performance

Smart Engineering, Lower Costs

More uniform temperature, when reduce hot spots, targeted thermal pathways, and extend tool life by up to 40%, due to up to 7 times higher thermal conductivity compared to the conventional tool steel.

Suitable Mechanical Performance

Suitable Mechanical Performance

Suitable Mechanical Performance

By combining the rugged durability of tool steel with advanced thermal pathways, PAX3D creates a "smart" insert that works with your process, not against it.

This website uses cookies.

We use cookies to analyze website traffic and optimize your website experience. By accepting our use of cookies, your data will be aggregated with all other user data.

Redefining Multi-Material Manufacturing

Unlock unmatched strength and thermal control in a single engineered part.